About This Item

Product Tech Specs

Length (mm) |

Fiber Type | Modulus |

Filament Diameter (um) |

Sizing Agent

| Sizing Level |

|---|---|---|---|---|---|

6.0 |

Carbon Fiber | Standard | 7 | Thermoplastic Epoxy | 1.0% |

12.0 |

Carbon Fiber | Standard | 7 | Thermoplastic Epoxy | 1.0% |

6.0 | Carbon Fiber | Intermediate | 5 | Thermoplastic Epoxy | 0.5% |

12.0 | Carbon Fiber | Intermediate | 5 | Thermoplastic Epoxy | 0.5% |

Scroll right to see more!

Product Details

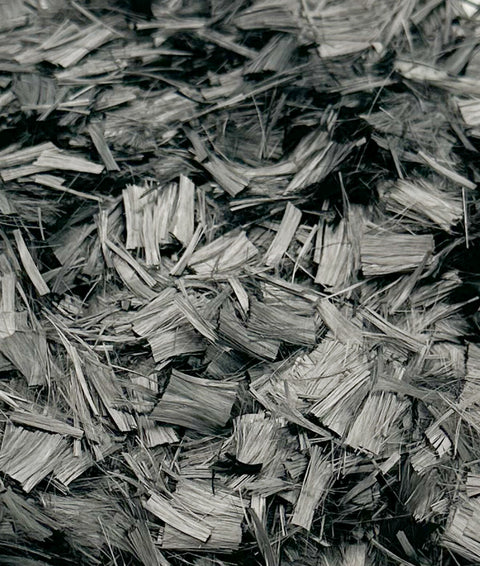

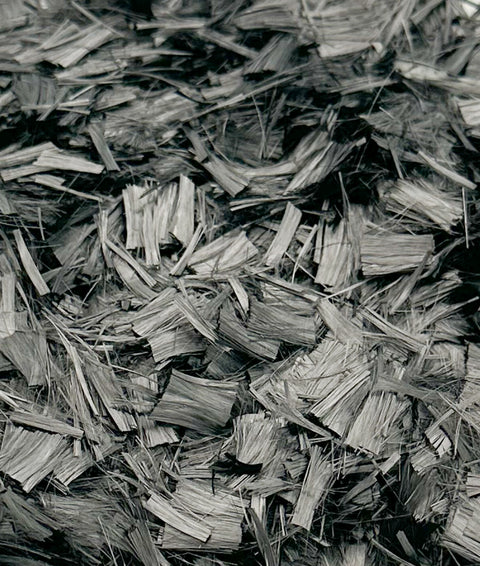

- Chopped carbon fiber with thermoplastic epoxy sizing

- Processed in the USA

- Offered in standard and intermediate modulus

- Available in various lengths optimized for your specific application

Packaging & Quantity

Product Performance

- 75% lighter & 10x stronger than steel

- High strength & modulus

- High thermal and electrical conductivity

- Corrosion resistant

- UV inert

Para-Aramid Resistance Guide

Carbon fiber boasts a range of exceptional properties that contribute to its widespread use across industries. Its excellent UV resistance allows it to maintain its strength and integrity even under prolonged exposure to sunlight. Furthermore, carbon fiber exhibits a wide temperature range, remaining stable and functional in extreme hot and cold environments. Additionally, its exceptional chemical resistance and compatibility make it resistant to corrosion and degradation, enabling its use in harsh chemical environments without compromising its performance or longevity.

This fiber exhibits poor flame resistance. It is not advisable to use in any application where an open flame is present.

Acid: Excellent resistant to most acids

Alkali: Good resistance to most alkalis

Organic Solvent: Generally compatible with a variety of organic solvents

Continuous Operating Temperature Range (°C): -50 to 300

Short Term Exposure (°C): Up to 500

Degradation Temperature (°C): 700